China Chongqing QIFU Machinery Co., Ltd.

was established in 2013. We have developed and grown in a long

history. During this period, we have absorbed outstanding

professionals and made continuous efforts to innovate and develop

to achieve company diversification.

After more than ten years of hard work in the

market, Chongqing QIFU Machinery Co., Ltd. now covers an area of

30,000 square meters and has thousands of employees. Adhering to

the corporate vision of "the first brand in China's industry,

creating a century-old classic of QIFU", it has now built a

headquarters base integrating operation, research and development,

production, and sales, and an assembly base integrating precision

processing and assembly, with an annual output of 8,000 The

production strength of 10,000 pieces of connecting sleeves has

formed a complete business chain of research and development,

manufacturing, sales, delivery, and service, and established and

implemented ISO9001 quality management system certification

throughout the business chain.

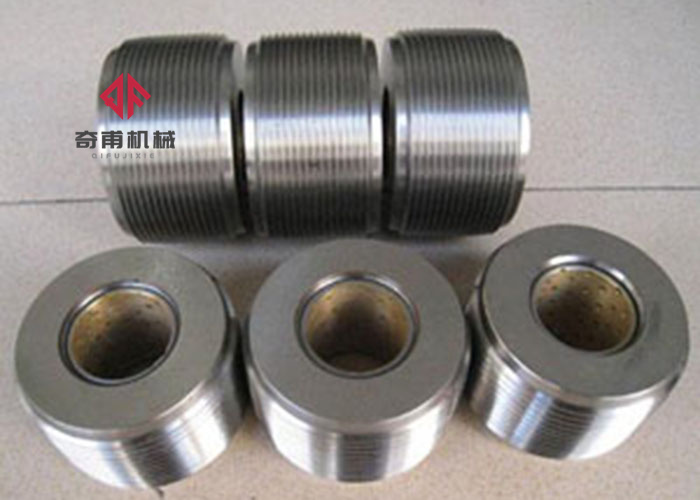

We are a well-known manufacturer, supplier and

exporter of rebar couplers in Mainland China. It specializes in the

production and production of steel couplers for the construction

and industrial fields, and has achieved excellent results in the

connection, upgrading and fixing technology of the construction

industry.

For high-precision manufacturing, we have

established an extensive infrastructure department equipped with

high-tech production machines and tools. After operation by our

well-trained professionals, we can meet the urgent needs of users

within the specified time frame. QIFU adheres to the "three noes"

principle of not accepting, not manufacturing, and not exporting

defective products, and is committed to providing high-quality

products for first-class enterprises and world-class projects to

make buildings stronger and safer.

QIFU people’s integrity management is the

cornerstone, technological innovation is the driving force, and

information management is the support. We will make every effort to

promote the development of the enterprise towards

innovation-driven, green environmental protection, and intelligent

manufacturing, and continuously improve the comprehensive strength

of the enterprise, adopting large-scale, service-oriented, and

high-end The road to sustainable development promotes the in-depth

integration of design, procurement, construction and other stages

to become a market-competitive manufacturer and service provider.

With a century-old QIFU, quality is king,

honesty management, and the rebirth of heritage.